전체 방송국 검색

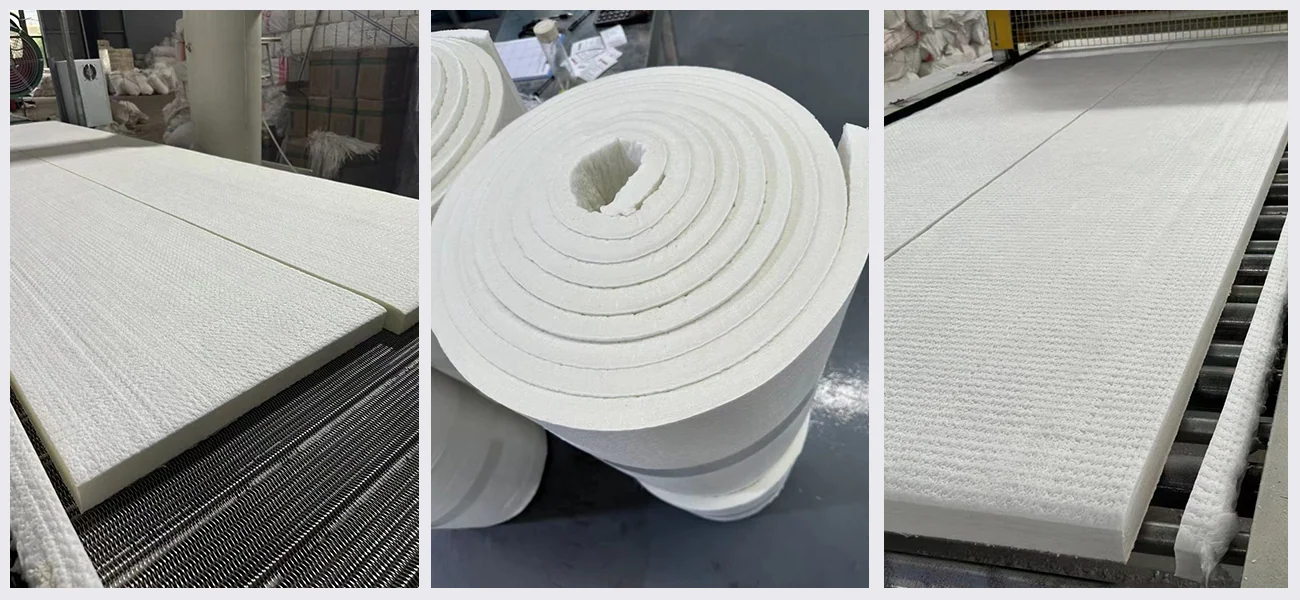

Ceramic fiber blanket is a lightweight, flexible, and highly efficient thermal insulation material designed to withstand extreme temperatures. Manufactured from high-purity alumino-silicate materials, the blanket is produced using advanced spinning and needling technology, resulting in excellent strength and durability.

Because of its low thermal conductivity, high tensile strength, and superior insulation performance, a ceramic fiber insulation blanket is widely used in furnaces, kilns, heaters, and other high-temperature industrial equipment.

Ceramic fiber blankets are capable of withstanding temperatures up to 1260°C (2300°F) or higher, making them one of the most reliable high temperature insulation blankets available.

With low thermal conductivity, ceramic fiber insulation minimizes heat loss and increases the energy efficiency of furnaces, kilns, and boilers.

Compared to traditional refractory materials, a ceramic thermal insulation blanket is much lighter and easy to cut, install, and maintain.

It resists most chemicals, reducing corrosion risks in harsh industrial environments.

Besides thermal insulation, ceramic fiber blankets also provide good acoustic insulation and mechanical shock resistance.

Ceramic fiber blankets are commonly used in furnace lining, kiln insulation, and heat treatment equipment to reduce energy consumption and extend equipment life.

In power plants, refineries, and chemical plants, ceramic fiber insulation blankets provide reliable high-temperature protection for piping systems, reactors, and boilers.

Because of their fire-resistant properties, ceramic fiber blankets are used in fireproofing systems, expansion joints, and thermal insulation of exhaust systems.

In aerospace and automotive engineering, ceramic fiber blankets act as lightweight refractory insulation materials, protecting components from extreme heat.

When selecting a ceramic fiber blanket for insulation, consider:

Compared to traditional refractory bricks and castables, ceramic fiber blankets offer:

For industries requiring high temperature insulation solutions, ceramic fiber blankets provide the perfect balance between performance, durability, and cost-effectiveness.

| Ceramic fiber blanket index | ||||||||

| Type | Common | Standard | High Purity | High Aluminium | Zirconia | |||

| Classification temperature (℃) | 1100 | 1260 | 1260 | 1360 | 1400 | |||

| Working Temperature(℃) | <1000 | 1050 | 1100 | 1260 | 1350 | |||

| Color | White | Pure white | Pure white | Pure white | Pure white | |||

| Density (kg/m3) | 96/128/160 | 96/128/160 | 96/128/160 | 128/160 | 128/160 | |||

| Shrinkage on heating(%) | -4 | -3 | -3 | -3 | -3 | |||

| (24 hours,density as 128/m3) | (1000℃) | (1000℃) | (1100℃) | (1250℃) | (1350℃) | |||

| Thermal conductivity by different temperature (w/m.k)(density as 128kg/m3) | 0.09(400℃) | 0.09(400℃) | 0.09(400℃) | 0.12(600℃) | 0.16(800℃) | |||

| 0.16(800℃) | 0.16(800℃) | 0.16(800℃) | 0.20(1000℃) | 0.20(1000℃) | ||||

| 0.20(1000℃) | ||||||||

| Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |||

| (density as 128kg/m3) | ||||||||

| Chemical composition(%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 | ||

| AL2O3+SiO2 | 96 | 97 | 99 | 99 | ||||

| AL2O3+SiO2+ZrO2 | – | 99 | ||||||

| ZrO2 | 15-17 | |||||||

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |||

| Na2O+K2O | ≤0.5 | ≤0.5 | 02 | 0.2 | 0.2 | |||

| Ceramic Fiber Blanket Size | ||||||||

| Size | ||||||||

| Length(MM) | Width(MM) | Thickness(MM) | ||||||

| Ceramic Fiber Blanket | 14400/7200/3600 | 610/1220 | 6-50 | |||||

| Other specifications can be customized according to customer requirements | ||||||||