Search the whole station

Scope of application

As a lightweight, high-temperature resistant, and low thermal conductivity refractory insulation material, aluminum silicate fiber finds its most extensive application in the furnace lining insulation of various industrial thermal equipment..

Aluminum silicate fiber (ASF) is a fibrous, lightweight refractory material made from aluminum silicate, offering excellent high-temperature resistance, thermal insulation, and sound absorption properties. It is typically composed of high-purity alumina (Al₂O₃) and silicon dioxide (SiO₂), making it suitable for thermal insulation and heat preservation in a variety of high-temperature environments.

Production Process and Technical Features

Production Method

The production of ASF fiber typically involves the following steps:

Raw Material Preparation: Select high-purity aluminum silicate raw materials, such as alumina, kaolin, and silica, and mix them in a specific proportion.

Fusing and Drawing: The mixed raw materials are placed in an electric arc furnace or resistance furnace, heated to above 2000°C to melt, and then drawn into fibers using a high-speed airflow.

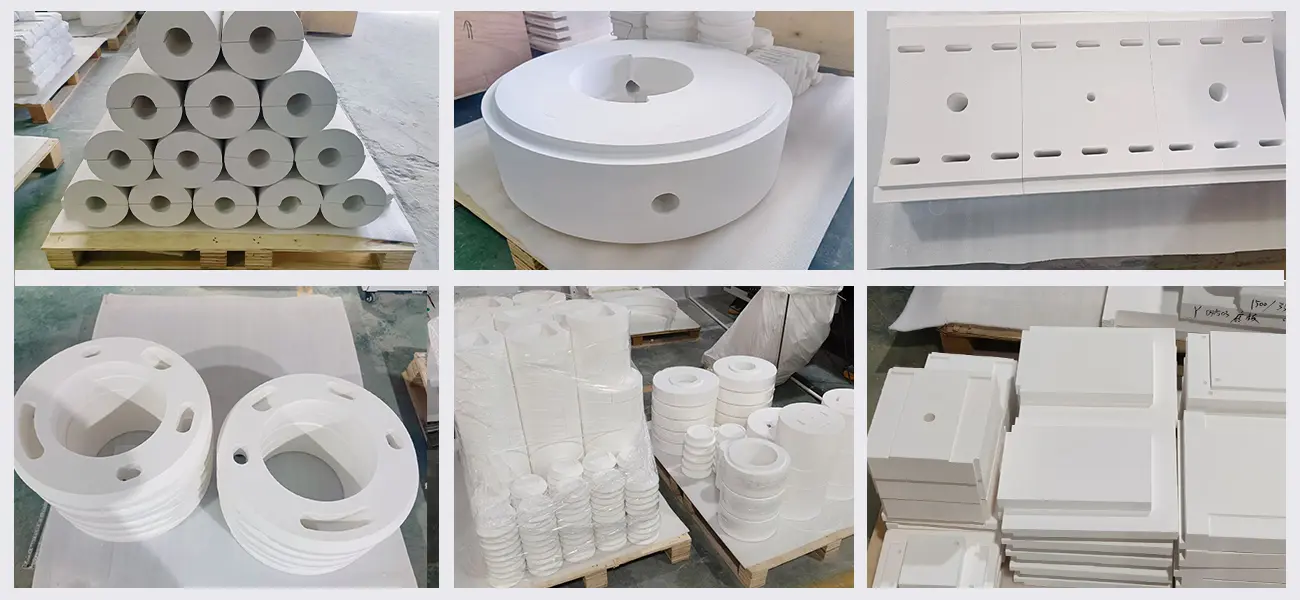

Secondary Processing: Depending on the desired product type (such as fiberboard, blanket, tube, rope, brick, etc.), the fibers are further processed to meet the needs of different application scenarios.

Core Characteristics

Aluminum silicate fiber has the following notable features:

High-temperature resistance: It can remain stable in high-temperature environments, with a maximum operating temperature exceeding 1000°C.

Low thermal conductivity: With a thermal conductivity as low as 0.13 W/(m·K), it offers excellent thermal insulation properties.

Lightweight and high-strength: It offers low bulk density, high strength, and excellent elasticity, making it suitable for a variety of installation methods.

Chemical stability: It is stable to most chemicals and is not susceptible to chemical reactions.

Sound absorption and noise reduction: Its porous structure effectively absorbs noise, improving the acoustic environment.

Applications and Market Demand

Main Applications

Aluminum silicate fiber is widely used in the following areas:

Industrial high-temperature equipment: It is used as a thermal insulation material for high-temperature furnaces and kilns in the metallurgical, electrical, mechanical, and chemical industries.

Building fire protection: It is used as a fireproof material in thermal insulation layers on building walls, ceilings, and other areas.

Catalyst carrier: It is used as a catalyst carrier in the chemical industry. Noise Absorption: Used for noise absorption and reduction in industrial equipment, such as high-temperature fans and exhaust ducts.

Market Demand Drivers

Building Energy Efficiency: With the global emphasis on energy conservation and emission reduction, demand for high-performance thermal insulation materials in the building sector continues to increase.

Industrial Demand: Demand for high-temperature thermal insulation materials continues to grow in industries such as metallurgy and chemicals.

Emerging Application Areas: With the rapid development of emerging industries such as new energy vehicles and aerospace, the application of aluminum silicate fibers in emerging fields continues to expand.

Future Development Trends and Challenges

Development Trends

Material Upgrade: Develop aluminum silicate fibers with higher purity and lower thermal conductivity to meet the needs of more demanding high-temperature environments.

Green Production: Promote the production of environmentally friendly aluminum silicate fibers to reduce energy consumption and pollutant emissions during the production process.

Intelligent Applications: Integrate digital technology to optimize the application design of aluminum silicate fibers and improve overall energy efficiency.

| Ceramic Fiber Heating Module | YX1260 | YX1400 | YX1500 | YX1600 | YX1700 | YX1800 | |

| Working Temperature(℃) | 1100 | 1200 | 1350 | 1500 | 1600 | 1700 | |

| Density(kg/m³) | 300-600 | 300-600 | 300-600 | 300-600 | 450-700 | 450-700 | |

| Linear Shrinkage(24H) (After Burning) (%) | ≤3.0 (1100℃) | ≤3.0 (1250℃) | ≤3.0 (1300℃) | ≤1.0 (1450℃) | ≤1.0 (1550℃) | ≤1.0 (1650℃) | |

| Thermal Conductivty Rate (W/m.k) | 400℃ | 0.084 | 0.084 | 0.084 | / | / | / |

| 800℃ | 0.128 | 0.125 | 0.125 | 0.160 | 0.160 | 0.160 | |

| 1000℃ | 0.176 | 0.174 | 0.200 | 0.210 | 0.210 | 0.210 | |

| Heating Element | Resistance wire | SiC heating element | SiC heating element | MoSi2 heating element | MoSi2 heating element | MoSi2 heating element | |

| Furnace Chamber Size | Customized | Customized | Customized | Customized | Customized | Customized | |

| The sizes and packaging can be customized according to your needs | |||||||