Search the whole station

Scope of application

Core High-Temperature Industries: This is its primary battleground, including heating furnaces and soaking furnaces in the steel industry, aluminum melting furnaces and copper processing furnaces in the non-ferrous metals industry, and cracking furnaces and conversion furnaces in the petrochemical industry.

Ceramic fiber modules have become one of the most widely used refractory insulation materials in industrial furnaces. With their excellent thermal stability, low thermal conductivity, and lightweight structure, ceramic fiber modules provide a durable and energy-saving insulation solution for various high-temperature applications. This article provides a complete SEO-optimized introduction to ceramic fiber modules, covering features, specifications, applications, and advantages.

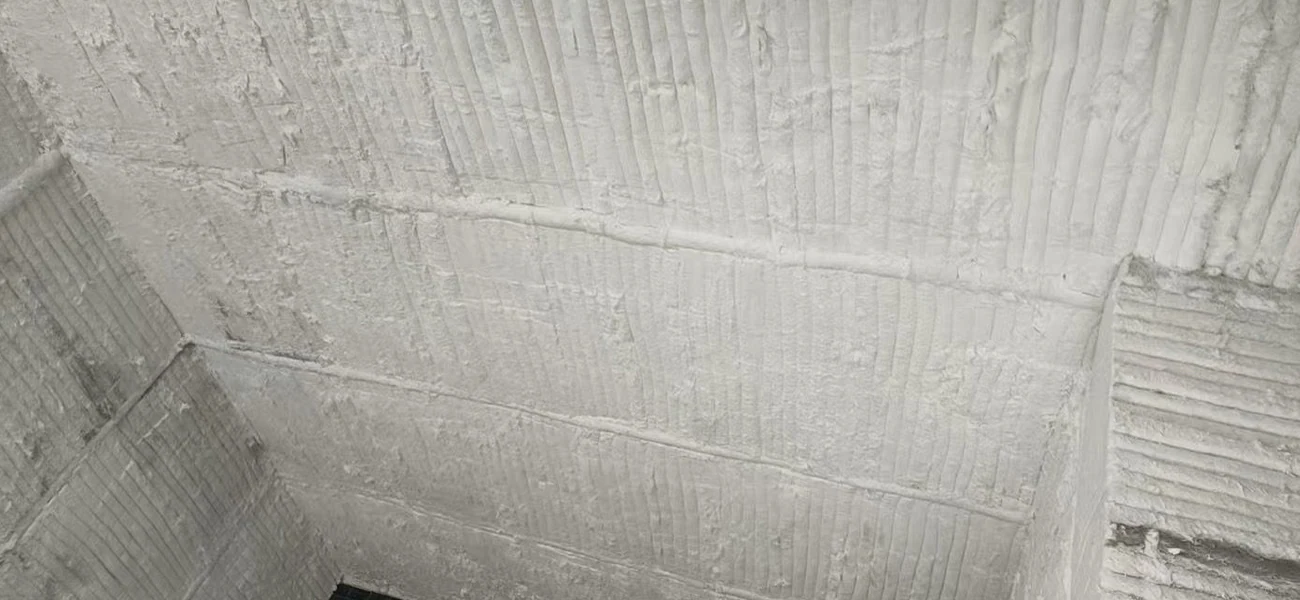

A ceramic fiber module is a pre-compressed, folded or stacked ceramic fiber blanket block designed for rapid installation on furnace linings. These modules are anchored by metal or ceramic parts and expand after installation to create a seamless thermal insulation layer.

Ceramic fiber modules are engineered for harsh industrial environments. Their performance characteristics make them ideal insulation materials for high-temperature systems.

Depending on the grade, temperature resistance ranges:

Ceramic fiber module insulation is widely used in:

Ceramic fiber modules offer many competitive benefits:

| Mode l | YX-1260 | YX-1400 | YX-1600 | |

| Name | 1260 | 1400 | 1600 | |

| Class if icat ion temperature (℃) | 1260 | 1400 | 1600 | |

| Operat ing temperature (℃) | 1000 | 1200 | 1500 | |

| Colour | wh ite | wh ite | wh ite | |

| Bu lk density(kg/m³) | 160-210 | 160-210 | 160-210 | |

| Shr ink(%) | 1100℃*24h | 1200℃*24h | 1500℃*24h | |

| 2% | 1.50% | 1% | ||

| Therma l conductivity(w/mk) | 600℃ | 0.12 | 0.13 | 0.08 |

| 800℃ | 0.16 | 0.2 | 0.13 | |

| 1000℃ | 0.22 | 0.22 | 0.17 | |

| 1200℃ | – | 0.3 | 0.28 | |

| Rebound rate(%) | 160kg/m³-5~8% | 160kg/m³-5~8% | 160kg/m³-5~8% | |

| 192kg/m³-10~15% | 192kg/m³-10~15% | 192kg/m³-10~15% | ||

| 210kg/m³-15~20% | 210kg/m³-15~20% | 210kg/m³-15~20% | ||