Pesquisar toda a estação

Scope of application

In the pharmaceutical industry, homogeneous reactors are crucial for the synthesis of active pharmaceutical ingredients (APIs) and intermediate compounds through enzyme catalysis and other liquid-phase reactions. Additionally, they are widely applied in polymerization processes for producing high-performance plastics and polymers.

A homogeneous reactor is a type of chemical reactor where the reactants, products, and catalyst all exist in the same phase, typically in the liquid or gas phase. This uniform phase distribution allows for smooth mass and heat transfer, resulting in a consistent reaction environment. Homogeneous reactors are widely used in chemical engineering, catalysis, biochemical processing, and energy research, due to their precise control of reaction kinetics and product selectivity.

The design and operation of a homogeneous reactor are crucial for achieving high conversion efficiency, controlled temperature, and optimal residence time. Unlike heterogeneous reactors, where the catalyst and reactants exist in different phases, homogeneous systems enable molecular-level interactions that often lead to faster reaction rates and greater yields.

In chemical engineering, a homogeneous reactor is defined as a reactor in which all reacting components are in the same phase. Most homogeneous reactors involve liquid-phase reactions, though gas-phase systems are also common in fields such as atmospheric chemistry and combustion studies.

The key features of a homogeneous reactor include:

Homogeneous reactors are typically modeled using differential equations that describe mass balance, energy balance, and reaction rate kinetics. Engineers often use continuous stirred-tank reactors (CSTR) or plug flow reactors (PFR) as homogeneous reactor designs depending on the process requirements.

The principle of a homogeneous reactor is based on uniform mixing and reaction within a single-phase system. The following key processes occur during operation:

The homogeneity ensures that the rate of reaction is not limited by diffusion, as is often the case in heterogeneous systems. Instead, the reaction rate depends primarily on intrinsic kinetics and thermodynamic conditions.

Designing a homogeneous reactor involves optimizing several engineering parameters, such as volume, temperature, pressure, mixing rate, and residence time. There are two common types of homogeneous reactor configurations:

A batch reactor operates in a closed system, where reactants are loaded, allowed to react for a fixed time, and then the products are discharged. This type is ideal for:

Batch homogeneous reactors allow precise control over temperature and reaction time, making them valuable for developing new reaction mechanisms.

A continuous homogeneous reactor, such as a CSTR or PFR, operates under steady-state conditions. Reactants enter and products leave continuously, maintaining constant concentration and temperature.

Continuous homogeneous reactors are commonly applied in industrial chemical synthesis, pharmaceutical production, and polymerization processes.

The effectiveness of a homogeneous reactor depends on several engineering parameters:

Homogeneous reactions are often sensitive to temperature variations. Proper thermal regulation ensures optimal reaction kinetics and prevents undesired side reactions. Advanced designs incorporate heat exchangers or cooling jackets.

For gas-phase homogeneous reactors, maintaining the right pressure ensures consistent reaction rates and prevents phase separation.

Efficient mixing prevents concentration gradients and ensures uniform reaction conditions. Agitators or mechanical stirrers are often used.

The time reactants spend inside the reactor directly influences the conversion rate. Short residence times favor fast reactions, while longer ones allow equilibrium to be reached.

In homogeneous catalysis, the catalyst is dissolved in the same phase as the reactants. This allows for direct interaction at the molecular level and provides several advantages:

Examples include acid-base catalysis, organometallic reactions, and enzyme-catalyzed processes.

However, catalyst recovery and recycling can be challenging compared to heterogeneous systems.

| Parameter | Homogeneous Reactor | Heterogeneous Reactor |

|---|---|---|

| Phase | Single (liquid/gas) | Multiple (solid-liquid/gas) |

| Reaction Rate | High (molecular level) | Limited by diffusion |

| Mixing | Complete | Partial |

| Catalyst Separation | Difficult | Easy |

| Typical Use | Liquid-phase catalysis, polymerization | Fixed-bed catalytic processes |

Homogeneous reactors are ideal when reaction precision and selectivity are priorities, while heterogeneous reactors are chosen for ease of operation and catalyst recovery.

These benefits make homogeneous reactors essential in fine chemical, pharmaceutical, and academic research applications.

Despite their advantages, homogeneous reactors face some operational limitations:

Advanced designs now include membrane separation, continuous-flow microreactors, and reactive distillation systems to overcome these issues.

Homogeneous reactors are applied in a wide range of chemical processes:

They play a vital role in research and development due to their flexibility and controllability.

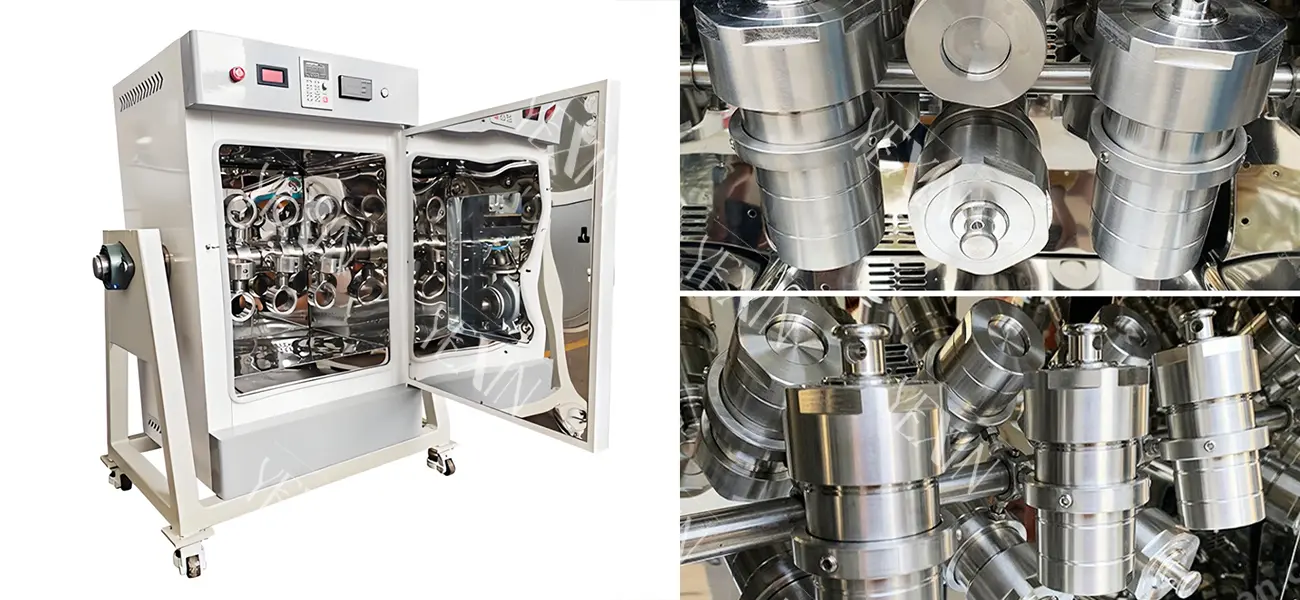

| Model | YXHR-4 | YXHR-8 | YXHR-12 |

| Maximum operating temperature | 280℃ | ||

| Long-term operating temperature | 260℃ | ||

| Constant temperature accuracy | ±1℃ | ||

| Heating method | Blast electric heating | ||

| Inner cavity size | 455*390*445mm | 455*390*445mm | 610*430*420mm |

| Dimensions | 450*540*980mm | 450*540*980mm | 1040*620*1000mm |

| Number of workstations | 4 | 8 | 12 |

| Heating power | 1.6kW | 1.6kw | 2kw |

| Power supply | 2.2kW | 2.2kW | 3kw |

| Speed | 5-70r/min stepless speed regulation | ||

| Inverter control method | VWVF control,DC braking 0.20-50.0Hz digital setting,direct start,built-in PID | ||

| Temperature control method | Intelligent temperature controller,30-segment programming PID self-tuning, intelligent automatic temperature rise and fall | ||

| Observation window | Double-layer tempered glass | ||

| Control thermocouple | PT100A model | ||

| Safety protection device Do | or opening heating and rotation power off,over-temperature alarm,automatic power off protection | ||

| Insulation materials | Aluminum silicate fiber insulation material | ||