Поиск по всей станции

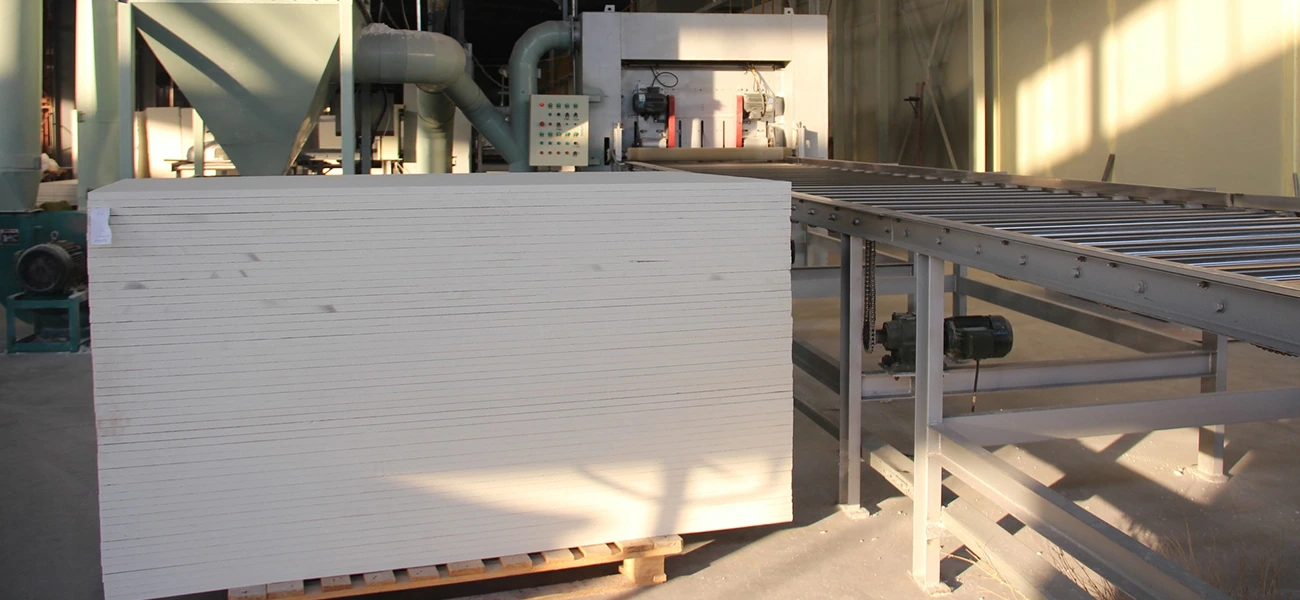

Ceramic fiber board is a rigid thermal insulation material made from aluminum silicate ceramic fibers. These fibers are produced through a melting and spinning process involving silica (SiO₂) and alumina (Al₂O₃). After fiber formation, a controlled vacuum forming and pressing technique is used to create a strong, dimensionally stable board.

Unlike flexible ceramic fiber blankets, ceramic fiber boards offer:

This makes them ideal for lining furnace walls, protecting heating zones, and reducing energy consumption in continuous high-temperature environments.

Ceramic fiber board is preferred across multiple industries due to its excellent physical and thermal characteristics. Below are the core features that contribute to its performance advantages.

Ceramic fiber board can withstand continuous exposure to temperatures ranging from 1000°C to 1600°C, depending on fiber type.

Common temperature grades include:

These properties make ceramic fiber boards ideal for kilns, furnaces, boilers, and thermal processing equipment.

One of the major benefits of ceramic fiber board is its exceptionally low thermal conductivity, which ensures minimal heat loss even under extreme temperature conditions.

Typical thermal conductivity values:

This directly results in:

The vacuum-forming process produces a dense, rigid structure that resists mechanical stress.

Advantages include:

This makes ceramic fiber boards suitable for furnace linings, access doors, fire protection panels, and hot-face insulation.

Compared to traditional refractory materials like firebricks:

This reduces installation time and overall project costs.

Ceramic fiber board is resistant to most chemicals except:

It is highly stable in environments involving:

The production process of ceramic fiber board involves several high-precision steps:

A high-purity mixture of:

is melted at 1800°C.

The molten mixture is converted into ceramic fibers using:

These fibers form the base material.

Ceramic fibers are combined with binders (organic or inorganic) and vacuum-formed into a wet board.

The wet boards are dried and fired at controlled temperatures, improving:

Boards are trimmed to standard sizes or custom-cut to meet industrial design requirements.

| Model | YX-1260B | YX-1400B | YX-1500B | YX-1600B | YX-1700B | YX-1800B | YX-1900B |

| Classification(℃) | 1260 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 |

| Working Temperature(℃) | 1000 | 1200 | 1350 | 1500 | 1600 | 1700 | 1750 |

| color | white | white | white | white | white | white | white |

| Bulk density(kg/m³) | 250~400 | 250~400 | 300~400 | 400 | 400 | 400~500 | 700 |

| Al2O3(%) | 43 | 45 | 60 | 64 | 75 | 80 | 87 |

| Al2O3+SiO2(%) | 98 | 98 | 98 | 98 | 99 | 99.5 | 99.5 |

| BaO(%) | <0.2 | <0.2 | <0.2 | <0.1 | <0.O5 | <0.O5 | <0.O5 |

| Shrinkage | 1100℃*24h -3 | 1200℃*24h -2.5 | 1400℃*24h -2 | 1500℃*24h -1 | 1600℃*24h -0.5 | 1700℃*24h -0.4 | 1750℃*24h +0.1-0.4 |

| Compressive strength | 0.3 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.8 |

| Burn reduction | ≤5% | ≤5% | ≤4.5% | ≤4.5% | ≤5% | ≤3.5% | ≤4% |