駅全体を検索

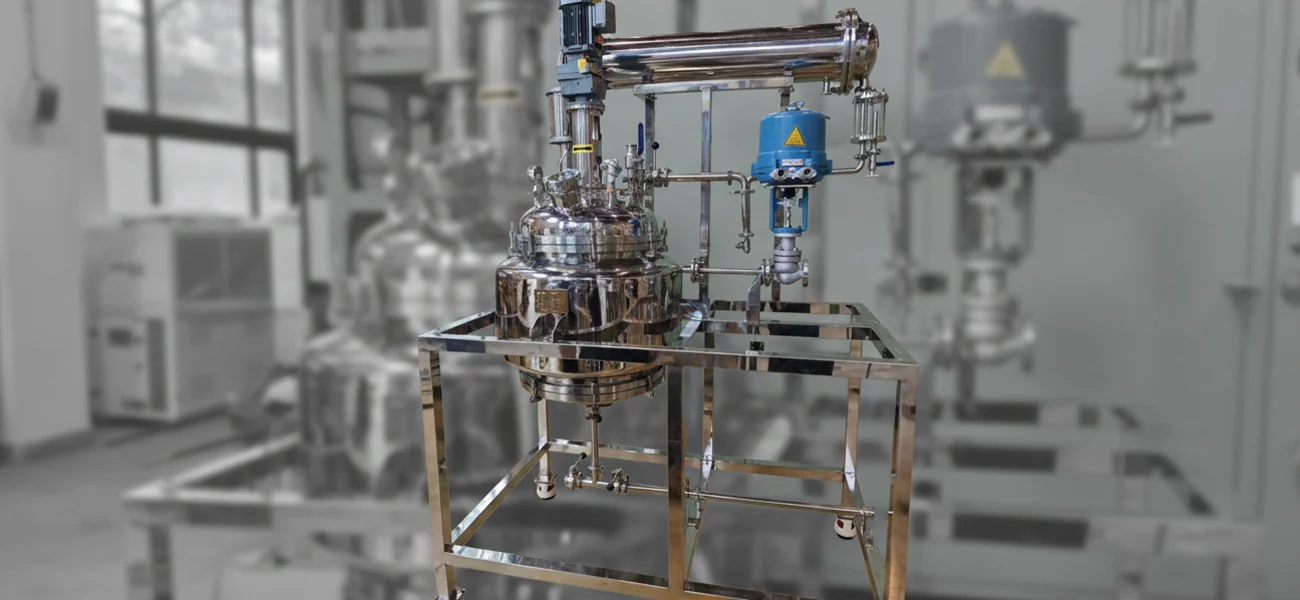

Stainless steel jacketed reactors are engineered vessels that allow controlled heating and cooling during chemical reactions. By combining a corrosion-resistant stainless steel body with an external heat-transfer jacket, these reactors deliver precise thermal management essential for complex and sensitive processes.

They are widely used in laboratories, pilot plants, and full-scale industrial facilities.

These properties ensure reliable operation in demanding environments.

Manufactured to pressure vessel standards for safety and durability.

Designed for uniform heat distribution and energy efficiency.

Ensures homogenous mixing and improved reaction efficiency.

Provides precise heating and cooling management.

Used for flexible production and specialty chemicals.

Suitable for large-scale and consistent output processes.

Used for reactions requiring reduced pressure conditions.

Stainless steel jacketed reactors can operate across wide temperature ranges, supporting both high-temperature reactions and rapid cooling cycles.

Precise control minimizes thermal gradients and improves product consistency.

Used for dyes, pigments, and specialty chemical production.

Applied in formulations, emulsification, and controlled synthesis.

Used for condensation, polymerization, and blending processes.

Supports sustainable processing and waste minimization.

Manufacturers offer extensive customization, including:

Customization ensures optimal integration into existing production lines.

Proper installation includes:

Correct operation maximizes efficiency and extends equipment lifespan.

Although initial investment may be higher, stainless steel jacketed reactors provide long-term value through reduced maintenance, high reliability, and consistent performance.

Advancements include:

These innovations enhance productivity and sustainability.

| Model | BSF-10L | BSF-20L | BSF-30L | BSF-50L | BSF-100L |

| Power(W) | 200(1:3) | ||||

| External dimensions(mm) | 540*480*1800 | 550*700*1830 | 550*700*1950 | 700*600*2050 | 700*800*2270 |

| Number of cauldron lid openings | 8 | ||||

| Temperature measurement port | 50.5 chuck / φ8 temperature measuring tube | 50.5 chuck / φ12 temperature measuring tube | |||

| Drop hole | 50.5 mm chuck/1000 ml funnel | 50.5 mm chuck / 2000 ml funnel | |||

| Return hole | 50.5 chuck / φ38 | 50.5 chuck / φ38 | |||

| sight glass | φ51 | φ89 | |||

| sight glass | φ32 | / | |||

| Feeding port | / | φ89 | |||

| Pressure gauge port | 50.5 mm chuck / integrated pressure gauge | ||||

| exhaust vent | 2-way exhaust valve | ||||

| Mixing hole | SUS316L propeller-type mixing impeller | ||||

| High and low temperature resistance (°C) | -120~260 | ||||

| Stainless steel thickness (mm) | φ3 | φ4 | |||

| Discharge valve port diameter | φ35 | ||||